Food packaging

Tin can – so simple and so necessary!

Safe food storage in metal containers was first introduced in France at the beginning of the 19th century, when Napoleon Bonaparte offered a prize to anyone who could preserve food for his army. Nicholas Appert discovered that food stored in tin cans and sterilized by cooking can be preserved for a longer period of time. Thus began the use of tin cans in the preservation and storage of food. Tin cans are still used today as one of the healthiest ways of preserving food. The imperative of every food producer is to preserve the freshness, quality, nutritional value, good organoleptic properties and safety of every product placed on the market. Metal packaging is characterised by a number of good qualities, it prevents the leakage of liquid or gaseous components, microorganisms or light and thanks to its excellent heat conduction, it is suitable for foods which are conserved by pasteurisation and sterilisation.

Lim Samobor d.o.o./LLC manufactures two-piece and three-piece tin cans which are suitable for the packaging of meat and fish products, fruit and vegetables, confectionary products, coffee, ready-made meals, food supplements, etc.

We are dedicated to manufacturing high-quality and safe packaging which fully meets the demands of customers in the food sector. We ensure a timely delivery of tin cans to customers in Croatia and abroad, in accordance with their requirements for design and size of tin cans. Our safety management system for packaging is in accordance with the international standard ISO 22000:2005 and encompasses all manufacturing, storage and distribution processes. This means that the entire tin can manufacturing process "from platinum to tin can” is supervised and continuously developed and improved.

We manufacture tin packaging for the following branches of the food

industry:

- Meat, fish and ready-made meals industry

- Fruit and vegetable industry

- Oil and fats industry

- Honey industry

- Dairy industry

- Confectionary industry

- Manufacturing of food supplements and cosmetics for special purposes

- Other food products (coffee, dried products, powder, granular and other products)

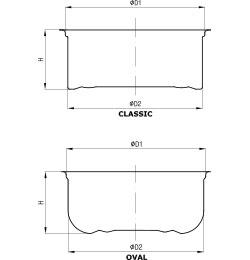

Drawn tin can

|

net weight [g] |

diameter

D1/D2 [mm] |

Height

H [mm] |

characteristic |

| 95 | 73/68 | 32 | BOWL-SHAPE |

| 100 | 73/68 | 33.7 | BOWL-SHAPE |

| 100 | 73/70 | 32 | CLASSIC |

| 150 | 73/73 | 40 | CLASSIC |

| 150 | 73/73 | 40.7 | BOWL-SHAPE |

| 150 | 73/73 | 41 | CLASSIC |

| 150 | 73/73 | 41.5 | CLASSIC |

| 300 | 99/99 | 44 | CLASSIC |

| 300 | 99// | 46 | BOWL-SHAPE |

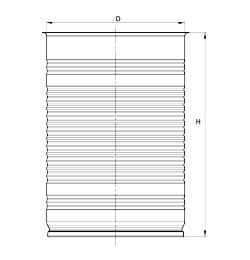

Three-piece food tin can

|

Diameter

D [mm] |

Height

H [mm] |

Volume

V [mm] |

Characteristic |

| 73 | 40 - 200 | 125 - 725 | EASY OPEN END, PEEL OFF, BOTTOM WITH PL. CAP |

| 80 | 50 - 200 | 165 - 940 | EASY OPEN END, PEEL OFF, BOTTOM WITH PL. CAP |

| 99 | 40 - 260 | 235 - 1750 | EASY OPEN END, PEEL OFF, BOTTOM WITH PL. CAP |

| 130 | 50 - 260 | 500 - 3000 | FLIP TOP LID |

| 153 | 50 - 300 | 720 - 4850 | EASY OPEN END, PEEL OFF, BOTTOM WITH PL. CAP |

| 163 | 50 - 250 | 800 - 4500 | EASY OPEN END, PEEL OFF, BOTTOM WITH PL. CAP |

| 200 | 50 - 300 | 1200 - 8250 | FLIP TOP LID |

| 220 | 50 - 300 | 1500 - 10000 | FLIP TOP LID |